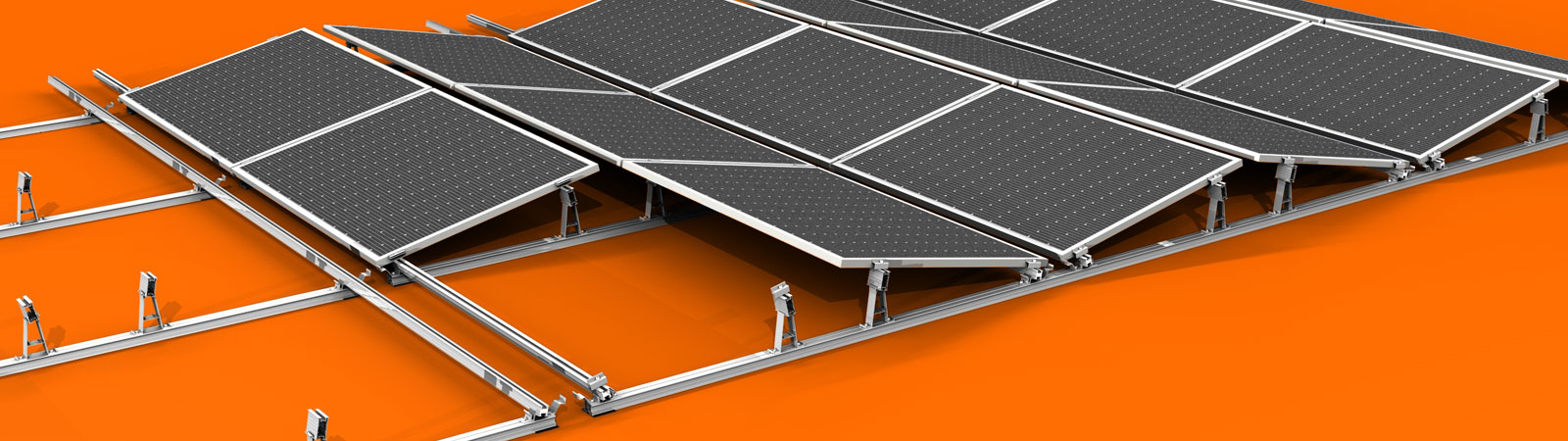

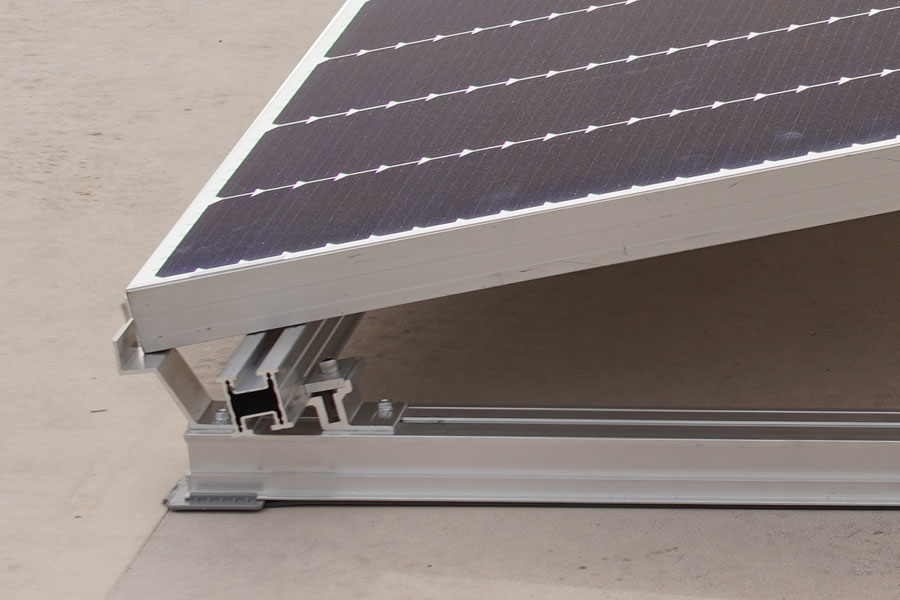

FD-OW low ballast elevation for east-west orientation

NEW! low weight, cheaper, for large modules and nevertheless stable!

With the further development of DICONAL® PV-mounting system we were determined to provide a new solution for east-west oriented flatroof mounting. The new system is lighter, cheaper and it offers more flexibility in using large modules. Our system is connected in a torsion-resistant manner. And the compatibility to all DICONAL® system components is still present even after 13 years of constant development. Also new is our mounting support FD-OW 32707. With the help of this „stencile“ the set up of the grid can be carried out precisely in a short time.

FD-OW Application

For flat roofs up to 5° tilt, that allow no roof penetration and only small extra load on the roof. The aerodynamic optimization prevents the PV system from sliping and blowing away.

Dowload documents:

- Data sheet FD-OW

- Data sheet collection DICONAL® System complete (6 MB) (German)

- Download Page (Flyer, Data sheets, Data collection sheet, Measurement sheet, GTC (German))

- DIBt® certification Z-14.4-827 (DICONAL® German)

- DIBt® certification Z-14.4-827 (DICONAL® English)

FD-OW Advantages

- Successfull Lightning protection test

- Aerodynamic optimization

- Low ballast needed

- Roof penetration free

- Stable against torsion

- Quick assembly thanks to project related configuration and premounted elevation frames

- Static system calculation

- We create a project based mounting- and ballastplan

- Module inclination 12°

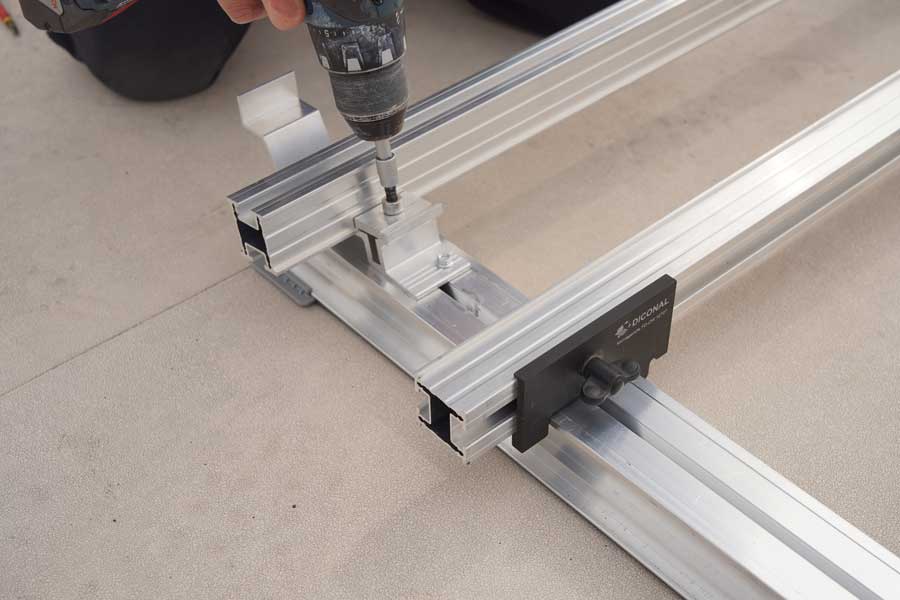

- Mounting support FD-OW 32707 for fast and precise alignment and connection of the frames

- Module change possible at any time, for example while planning, repowering or repairing the plant

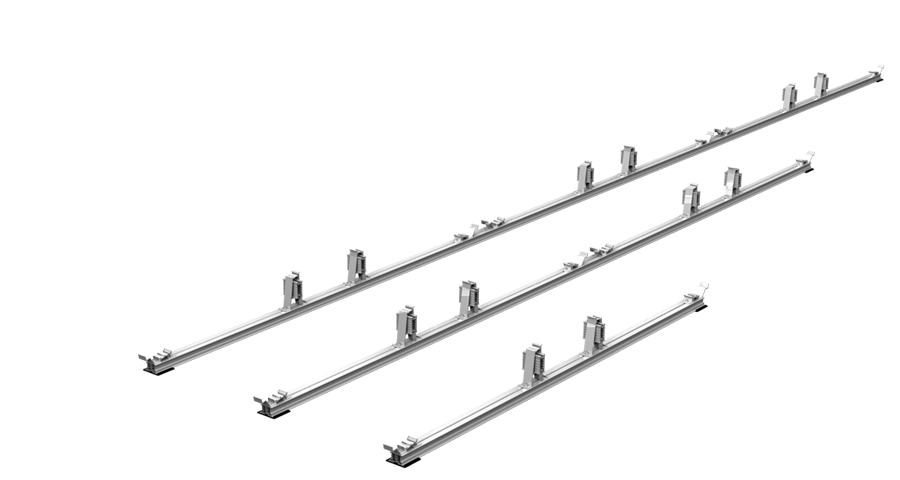

- all components are pre-assembled

- no sawing or drilling on the roof

- fast and error-free mounting

- special anti-slip coating is premounted,

- a building protective matting is needless

- Protection of the roof membrane by pre mounted profile end caps

- compatible with all DICONAL®system components

- the roof remains unchanged i.e. a deconstruction of the PV system can be done easily

Technical information

- 12° Elevation angle

- Modules are mounted horizontal

- Row spacing is determined by the module lengths (see assembly aid FD-OW 32707 below)

Material profiles and clamps: Aluminium / ENAW 6063

Screw material: stainless steel / 1.4301

DICONAL® FD-OW-2 / -4 /-6 und FD-OW -XL is configured as a complete project related system

System variant

FD-OW-2 (for 2 modules)

FD-OW-4 (for 4 modules)

FD-OW-6 (for 6 modules)

FD-OW-2-XL (for 2 modules > 1100mm width)

FD-OW-4-XL (for 4 modules > 1100mm width)

FD-OW-6-XL (for 6 modules > 1100mm width)

Mounting tools

Hexagon allan-key 6mm

Adjusting Mounting support FD-OW 32707

The distance between the preassembled frames is determined by the length of the modules. We provide the „assembly stencile“ to make it easy to bring the rows in the correct distance.

Insert the two mounting aids in a P-40 profile. Position the module right and left on the edges (illustration 1-3) - adjust - fix and repeat the adjustment for further module rows.

Mounting

- Measure + mark with chalk line (note edge regions) + position preassembled elevation frames

- Align the frames with the DICONAL® Mounting support FD-OW 32707 and fix them in the perfect position

- Tighten the P-40 connection profiles in the clamp position - Use the Mounting support at any position

- Now the P-80 profile section can be taken out of the transport position and be fix them in the right position with the connector

- Place the ballast according to the plan

- Module fastening with MMK and MEK module clamps on the P-40 and P-80 profiles

- Important: The modules must be placed at the bottom in the positioning angle!

- Important: Wind optimization requires module positioning according to the project plan. The minimum distance between the top edges of the modules is 130 mm (Figure 7, right).

- The connection profiles P-40 can be connected with a P-80 connector to a continuous profile level