GA - Application

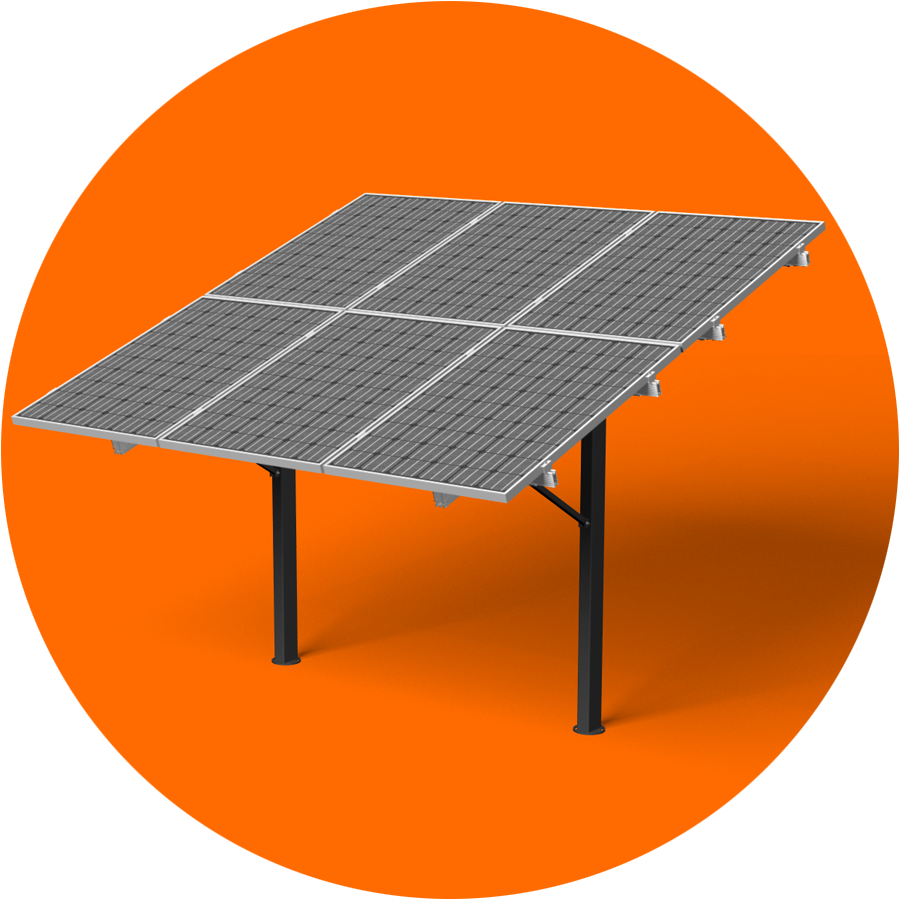

Freestanding PV systems can be implemented with our DICONAL® GA system.

Requirement: The subsurface must be suitable for anchoring with just two supports. Mounting on ground screws is only possible where the required depth can be achieved.

Building permits

Note regarding building permits for garden PV systems: For independent PV systems, operators must apply for a building permit depending on the size of the system. In almost all federal states, the permit requirement applies to open-space systems with a length of 9 m and a height of 3 m or more. A DICONAL® garden system with, for example, 14 standard modules is approximately 8.2 m long and a maximum of 2.7 m high (at a 20° inclination). In any case, you should contact the responsible municipal authority in advance.

Dowload Dokuments:

- Data sheet GA (German)

- Data sheet collection DICONAL® System complete (6 MB) (German)

- Download Page (Flyer, Data sheets, Data collection sheet, Measurement sheet, GTC (German))

- DIBt® certification Z-14.4-827 (German)

- DIBt® certification Z-14.4-827 English

GA - Advantages

- Only 2 posts for a single bay with 6 modules

- Easily expandable - only 1 post is required for 4 additional modules

- Minimal space restrictions

- Head adjustable in 5° increments from 0° to 20°

- Inclined bracing continuously adjustable in the groove

- 0° is intended for OW elevation, similar to FD OW

- Support spacing Ⓒ variable from 2300 mm to 2700 mm, depending on the structural design (wind, snow load)

- The base is easily rotatable (photo below) with an elongated screw hole

- Can be mounted with ground screws or concrete foundations

- Wind bracing is not required in most cases - however, the ground anchoring must be clarified on site

- Attachment points for any necessary wind bracing are already integrated

- Compatible with all DICONAL® system components

- All steel components hot-dip galvanized, and powder-coatable in any RAL color upon request

Technical information

GA mounting racks are designed specifically for each project. Modules are mounted vertically. A single rack provides mounting space for 6 modules. Expansion by 4 modules is possible with one additional rack. 0° is intended for an east-west elevation, similar to FD-OW.

Material support post: steel post hot-dip galvanized, and powder-coatable in any RAL color upon request

Material mounting profile + clamp: ENAW 6063

Screw material: V2A

Installation

- Preparation: Install screw or concrete foundations with a suitable mounting plate.

- The studs are bolted to the installed foundations.

- Install the P-120 mounting profiles at the desired angle (0°-20° in 5° increments).

- Screw the cross brace to stabilize the angle between the studs and the P-120 profile.

- Mount the P-80 profiles with KV-40 clamp connectors to the P-120 profile at the module attachment points.

- The final step is to clamp the module to the P-80 profile. To do this, tighten the module clamp screw to 10 Nm.